|

|

|

|

|

|

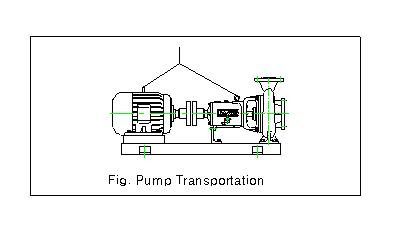

1. Transportation

1-1 In transit, the pumps should remain

level and should be protected from shocks or drops.

1-2 Especially, when wires or ropes

are used for the transport, care should be exercised to prevent

The

damages of accessories such as corks.

1-3 When wires or ropes are used for

the transportaion, the pumps must be moved as shown

|

|

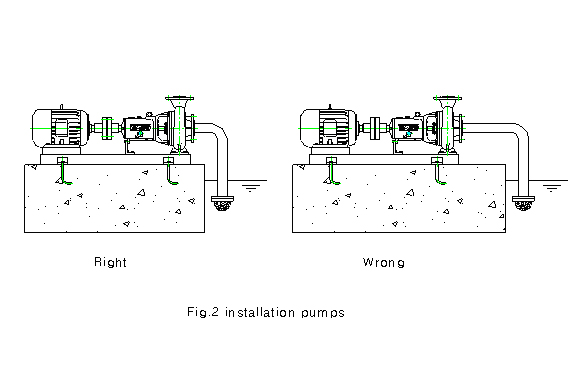

2.

Installation

2-1 Use concrete to fix the foundation

bolts on a firm ground and then firmly install individual pumps.

2-2 Use the bottom of the joint bed

to perfectly level the ground on which the pump is installed.

2-3 The space should be as large as

possible to facilitate easy access the checking and installed.

2-4 When the horizontal pump is to be

installed as shown in the Fig. 2 the suction distance should

be

as short be possible.

|

|

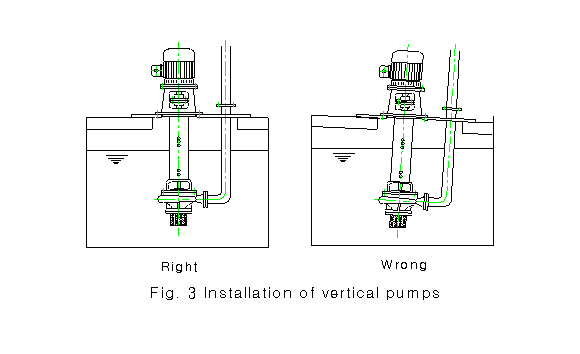

2-5 When the vertical

pump is to be installed, precise perpendicularity and horizontality

must be

established in connecetion with the cistem tank as shown is

the Fig.3

|

|

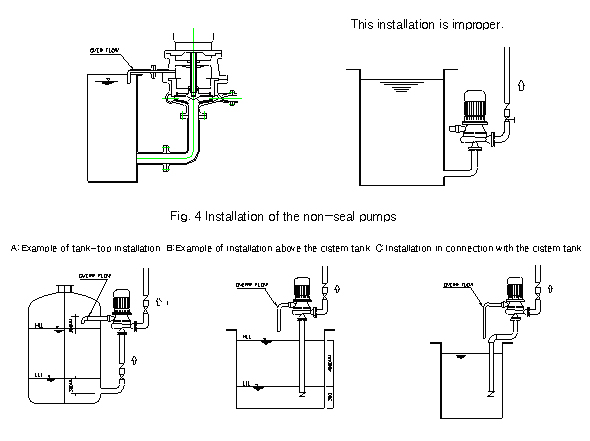

2-6 When non-seal pump

is to be installed, it should be installed within the boundary

between the

back of the pump impeller and the central line the overflower

pipe.

|

|

3.

Piping

3-1 The suction piping should be instslled for each individual

pump and in parallel to one another.

3-2 The suction piping should be as straight and short as possible

and be supported to prevent any

strains on the pump.

3-3 In order to avoid air pocket, the suction pipe should have

the upward slant of 1/50~11/100.

3-4 The piping flanges should be bolted on the same imaginary

line with the pump flanges.

3-5 During the piping work, care should be taken to prevent

any impurities such as welding slags,

bolt, tools and glovers, form entering the pipeline.

3-6 Install the check valve to prevent backward rotation of

the pump during the shutdown caused by

the

backflow of the liquid.

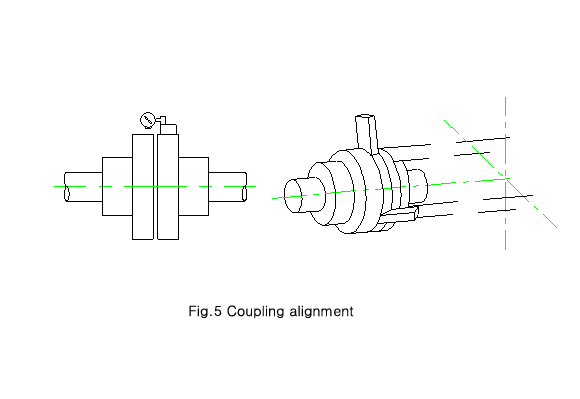

4. Coupling alignment

When the installtion and the pipung

work are completed, align the axis between the pumps and

The motors.

4-1 Loosen the motor securing bolts

and coupling bolts.

4-2 Attach the dial gauge on the outer

diameter of the motor coupling and install the needles at

the

side

of the pump.

4-3 Move the dial gauge so that the

motor axit comes within the up /down and sideway deflection

of

0.05mm. Measurer the coupling clearance with the thickness

gauge at 4 points by the interval

of

degree. aign so that the clearance deviation is less than

0.05mm. secure the motor in place.

|

|

5.

Preparation for operration

5-1 Cheek the iubrication of the bearing.

5-2 Rotate the coupling with hands to feel any contact of surfacee

inside it.

5-3 Energize the motor and momentatily

turn it on to cheek if it rotates in the same direction with

that of the

pump. (if the direction is reverse, a great damage may be caused

to the pump. Checking the

direction of rotation is very important)

5-4 If the direction of the pump rotation is consistent with

of the pump. Tighten the coupling bolts.

5-5 Check if there are any loose bolts and nuts.

5-6 Fully open the suction valve and completely close the discharge

valve.

5-7 Prime the pump topurge the air.

5-8 If the liquid level is higher then the center of the axis,

open the air discharge cork, suction valve

and the discharge valve to fill the pump.

6. Operation

6-1 Energize and rotate the pump to the normal rate of rotations.(Never

idle run the pump. Make sure

that the suction is underway)

6-2 When the normal rate of rotation is reached, slowly open

the valve until the pressure gauge at the

dischage side reaches the standard pressure, in order to set

the pressure.

6-3 If the pump is run below the standard pressure, the overload

may damage the motor.

The pump must always run at the standard pressure.

6-4 If any failure or defect is found while the pump is running,

immediately shut the pump pff and do

not turn the pump on again until the failure or defect is

removed.

6-5 Running with the discharge valve closed(closed operation)

has an adverse effect on the pump.

Limit the duration of the closed operation .(The liquid level

should be higher than the LOW when

The pump is run this way.)

7. Operatinfg-Stop

7-1 Fully closed the discharge valve and cut the power off

to stop the rotation.

7-2 Cut the supply of various liquids from the external sources(cooling

water, flushing liquid, etc)

7-3 If the pump operation is to be suspended for a prolonged

periond, completely remove the liquid in

the casing by opening the water drain in order to prevent

any damage from the winter freezing.

8. Checks and maintenance

8-1 Checks

1-1 Weekly : leakage at packings and temperature of bearings.

1-2 Monthly : Connection of coupling.

1-3 Quarterly : Lubricating and insertion of one set of packings.

1-4 Yearly : Overall condition of the pump.

8-2 Replacements

2-1 Oil replacement

1) 1st replacement : complete replacement after 100hours of

trial run.

2) 2nd replacement : complete replacement after 300hours of

run since the 1st replacement.

3) From the 2nd replacement, the oil will be replaced at every

800hours of running.

* Re- greasing : first after 100hours of trial run and then

at every 400hours of run.

8-3 Lubrication

|

| Makers |

Oils |

Greases |

| Mobille |

DTE Heavy |

Mobilux Grease - 2 |

| Shell |

Shell Tellus #46 |

Calcium Grease - 2 |

| Caltex |

Regarl & OPE/F |

Multi-Fak Grease - 2 |

| Yukong |

hARMONY #56 |

Crown Grease - 2 |

|

8-4 Packing replacement

1) Remove al the old packings, clean out the inside of the box

and apply the lubricant.

2) Cut the necessary amount of packing so that, when the cut

surface is wrapped around the axis,

Each packing may be aligned in parallel.

3) Insert the packing one at a time and tighten the push bolts

one at a time.

4) Fix the packings so that the cut faces of each packing may

be placed at the right angle.

5) When the packings

are inserted, the center of the lantern ring should meet the

water inlet.

9. Dissembly and assembly

9-1 Dissembly

1) Loosen the coupling

bolts.

2) If necessary,

loosen the power cord of the common bed.

3) Remove the casing

bolts and nuts.(If necessay, remove the oacking push nuts.)

4) Remove the casing,

using the dissembly bolts. Care not to damage the impellers

and axis.

5) Remove the impellers,

sleeves and bearings from the axis, without applying too mucttorque.

6) Place the removed

parts inan orderly mannaron a cloth or paper, which is laid

on a clean surface

In

order oder to prevent any confusion when the pump is put together

again.

|

| Troubles |

Causes |

Troubleshootion |

| Water does

not run. |

Suction pipe or the strainer

clogged |

Clean out them. |

| Air in the suction. |

Check and repair the suction

pipe system. |

| Revers rotation. |

Change the wiring. |

The stroke

and the discharge

Do not reach the standards. |

Minor air inducement. |

Check and repair the suction

Pipe system. |

| Cavitation. |

Replace the suction pipe

(minimizing the loss) or lowerthe location of the pump. |

| Wear and clogging of the impeller. |

Clean or replace the impeller. |

| Slow rotqations. |

Check and repair the motor and

The power |

| Damaged discharge pipe. |

Check and repair the discharge

Piping. |

Pump check point different from

The actual stoke and flow. |

Check and repair the discharge

Pipe system. Replace the pump. |

| When initial

water dischargeIs quickly followedby no waterflow |

Air pocket in the suction pipe. |

Repair the suction pipe. |

| Air influx. |

Check and repair the suction pipe

And the packing. |

| Low water level(suction stroke) |

Low the position of the pupm. |

| Overload |

Poor alignment. |

Re-align the system. |

| Excessive discharge. |

Close the discharge valve to

The pump |

| Bended axis. |

Replace the axis. |

| Impurities in the impeller. |

Dismantle and clean the impeller. |

| Bearing overheated. |

Improper type of iubricant or

Lack of lubrication. |

Replace and refill the lubricant. |

Defective bearings or poor

Bearing assembly. |

Replace and re-assemble the

bearing. |

| Poor alignment. |

Re-align the system. |

| Poor impeller balance. |

Correct or replace the impeller. |

| Severe pump

vibration. |

Poor alignment. |

Re-align the system. |

| Poor installation. |

Correct the installation. |

| High discharge. |

Close the discharge valve. |

| Poor impeller balance. |

Correct or replace the impeller. |

| Curved axis. |

Replace the axis. |

|

| |

| |

| |

|

|